RFID fixed asset management has become a development trend

Fixed asset management (EAM) is a core and important component of enterprise management, and has also become a difficult point in control work. Due to its high value, long service life, and dispersed usage locations, EAM poses significant management challenges. Adopting a digital management model for assets is the trend of future asset management development. Asset lifecycle tracking management transforms asset management from static management to dynamic management. Through the application of RFID automatic identification technology, RFID wireless radio frequency systems are introduced into fixed asset management. This not only greatly improves work efficiency, saves labor costs, and greatly reduces the occurrence of various errors that cannot be avoided in manual inventory, but also more accurately grasps the stock and distribution status of fixed assets, and improves usage efficiency.

The RFID fixed asset management system mainly provides information management for the entire lifecycle of enterprise fixed assets. The control process includes modules such as asset application, warehousing, requisition, borrowing, return, allocation, transfer, maintenance, scrapping, cleaning, return, inventory and low value consumables, depreciation, etc. RFID technology optimizes the inventory process comprehensively, reduces workload, and increases inventory efficiency. The digital management of RFID fixed assets has become a development trend.

The digital application effect of RFID fixed asset management

Improve inventory speed: RFID handheld terminals can quickly conduct inventory, increasing inventory speed by several times and automatically generating inventory reports.

Real time monitoring of asset information: For each asset, real-time information such as total quantity, location, usage status, user, depreciation amount, etc. can be obtained.

Full lifecycle management: RFID completes the entire lifecycle management process of asset addition, transfer, requisition, inventory, maintenance, scrapping, etc.

Asset whereabouts can be traced: Whenever an asset is applied for, borrowed, transferred, repaired, etc., corresponding operation records will be generated and submitted to the asset administrator for approval, enabling real-time standardized asset operations and traceable whereabouts.

Improve management efficiency and reduce error rate: Through the RFID asset management system, automated asset management has been achieved, increasing management efficiency by more than half and achieving the expected application effect within a certain range.

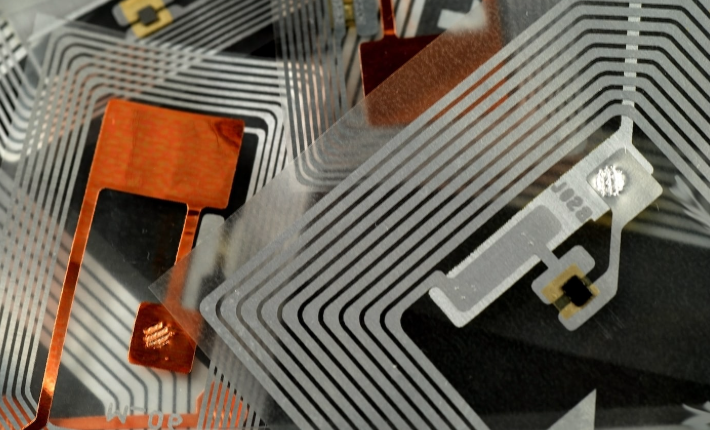

Install RFID electronic tags for one-to-one identity binding on each fixed asset that needs to be managed, and install RFID reader/writer devices on channels where fixed assets may flow. When fixed assets move, the system automatically tracks their location and determines a new direction. RFID handheld devices and fixed channel door readers are used for fixed asset inventory. RFID technology has greatly improved the efficiency of inventory and formed automated and information-based collection. At present, RFID handheld terminal devices can be used for irregular inspections during asset inventory to check asset management. RFID readers can simultaneously identify and read RFID electronic tag information on multiple fixed assets, with batch processing, instant completion, and higher efficiency.

By binding the identity of an RFID electronic tag to an asset, rapid batch sensing inventory can be achieved, making the inventory work that used to rely on paper data statistics efficient and accurate, matching accounting with physical objects, avoiding asset loss, improving asset utilization, and making asset management informationized and digitized.